With more than twenty years of practical experience in renovating, repairing, and enhancing residences, Lee has been offering home improvement guidance for many years.

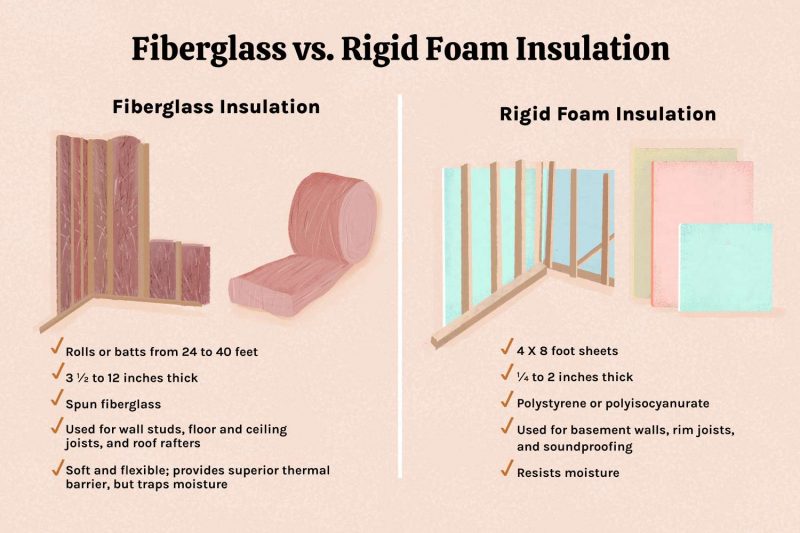

Home improvement retailers offer two primary types of insulation: fiberglass and rigid foam, both intended for residential applications. Although there are some similarities in their uses, neither is inherently superior to the othereach is suited to specific situations. For instance, rigid foam is often utilized for insulating basement walls, as it effectively withstands moisture from the masonry. On the other hand, fiberglass batts are generally installed between wall studs, as well as in floor and ceiling joists, and roof rafters.

If you’re planning a home renovation and are deciding between foam board and fiberglass insulation, continue reading for further details.

- sheets measuring 4 feet by 8 feet

- Thickness ranging from 1/4 inch to 2 inches.

- Polystyrene or polyisocyanurate foam

- Rolls or batts ranging from 24 to 40 feet in length.

- Thickness ranging from 3.5 to 12 inches.

- Fiberglass that has been spun

Contents

Rigid Foam vs. Fiberglass Insulation: Key Distinctions

Rigid Foam Insulation

Rigid foam insulation is available in 4-by-8-foot sheets with thicknesses ranging from 1/4 inch to 2 inches. Additionally, it can be found in large bundled panels, which are connected at the ends in an accordion fashion, designed for use as exterior sheathing.

Rigid foam insulation is made from one of three types of materials:

- Premium, eco-friendly polyisocyanurate

- Expanded polystyrene

- Expanded polystyrene foam

Rigid foam exhibits excellent performance in moist conditions, maintaining its dimensions without splitting or cracking. Although spray foam insulation, when applied in wall cavities, cures to a solid form, it is not classified as rigid foam insulation. Nevertheless, rigid foam boards can be a suitable alternative to spray or fiberglass insulation in areas like wall cavities that are prone to moisture.

Fiberglass Thermal Insulation

Fiberglass insulation is made up of densely compressed long rolls or separate batts, which are individual sections of spun fiberglass strands.

Unlike rigid foam, fiberglass is pliable and adaptable. The countless air pockets within fiberglass insulation create an excellent thermal barrierhowever, it can also retain moisture, which may result in the development of mold and mildew. Therefore, fiberglass should be avoided in any situation where moisture is even slightly present.

Fiberglass insulation is commonly available in batts or rolls that are tailored to fit standard wall and ceiling spaces, where the framing is typically spaced either 16 or 24 inches apart, center to center. The thickness of the batts varies from 3 1/2 to 12 inches. Rolls of fiberglass insulation can measure between 24 and 40 feet in length, while batts are typically bundled and measure around 93 inches.

Fiberglass insulation can come in rolls or batts, often with a paper facing to make it easier to attach to framing. On the other hand, unfaced batts or rolls are more suitable for use as a blanket insulation.

Applications

Rigid Foam Insulation

- Continuous insulation on the exterior: Rigid foam serves as sheathing, providing a seamless layer of insulation that is affixed to the outer walls prior to the application of house wrap and siding.

- When it comes to basements, rigid foam board insulation is superior to fiberglass insulation for indoor applications. It is the preferred option for walls that come into contact with masonry, primarily the exterior walls in basement constructions, with the exception of walls that face daylight in walk-out basements. Rigid foam is more resistant to moisture compared to fiberglass.

- For garage doors and floors, rigid foam insulation is the most effective option, while either insulation type can be utilized for the walls of the garage.

- Radiant heating systems utilize rigid foam as an insulating layer beneath the flooring to enhance thermal efficiency.

- Rim joists located at the perimeter of the foundation can be insulated using rigid foam blocks that are precisely cut to fit the gaps and secured with caulk. In certain cases, it is possible to combine different insulation methodsfor example, if the concrete blocks contain hollow spaces, they should be filled with loosely packed fiberglass insulation before applying the rigid foam.

- Additional applications: Rigid foam can serve as a sound barrier for interior walls or isolate areas that lack climate control. It can also be utilized to create temporary privacy partitions in communal living spaces such as apartments or dorms.

Fiberglass Thermal Insulation

- Exterior walls: The primary function of rolled fiberglass insulation is to occupy the spaces within above-grade exterior walls that can be accessed from the interior. In the case of new builds or significant renovation projects where the wall surfaces are not yet in place, faced fiberglass batts are the preferred insulation option. For walls that are already finished, blown-in cellulose insulation or spray foam is typically utilized to enhance insulation.

- Attics: To insulate the attic effectively, thick fiberglass batts or rolls are utilized to minimize heat loss through the ceiling and roof. Faced batts are typically placed between the joists, while an attic blanket made of unfaced batts can be spread over the joists. For optimal insulation performance, a combination of joist cavity insulation and an attic blanket can be employed. Additionally, blow-in cellulose insulation serves as an alternative to fiberglass and can be applied over existing fiberglass insulation to enhance thermal resistance.

- Floors: The spaces between joists in unheated crawl spaces or basements are commonly filled with fiberglass batts for insulation. This fiberglass insulation in the flooring helps to reduce sound transmission in two- or three-story houses.

- Rim joists: The areas between joists situated above the foundations can be insulated with loosely packed fiberglass to minimize heat loss. This insulation can be applied in conjunction with rigid foam, where fiberglass fills the gaps at the tops of concrete block walls, and rigid foam blocks are utilized to seal the joist spaces above the foundation walls.

- Alternative applications: Loosely packed fiberglass is frequently utilized to fill minor openings around window and door frames, as well as the areas where pipes and wires pass through the outer walls. Spray foam is another option employed for these tasks.

R-Values

The thermal resistance of different construction materials is quantified by their R-value, which reflects their insulating capabilities. A higher R-value signifies superior insulation performance.

The R-values of rigid foam and fiberglass insulation are primarily influenced by the thickness of the insulating material. Rigid foam insulation offers a higher R-value per cubic inch compared to fiberglass. If your primary objective is energy conservation and there are no other considerations like moisture, rigid foam insulation might be the best option for you.

Rigid Foam Insulation

The R-values of rigid foam vary from R-1 for sheathing panels that are 1/4 inch thick to R-15 for panels that are 3 inches thick. It’s important to note that the R-value is influenced not only by the thickness of the material but also by the type of foam and the facing material utilized.

Fiberglass Thermal Insulation

The R-values of fiberglass insulation typically vary between R-11 and R-38, depending on the thickness options that are most widely accessible.

- 3.5 inches: R-11

- 3.625 inches: R-13

- 3.5 inches (high density): R-15

- 6 to 6.25 inches: R-19

- 5 1/4 inches (high density): R-21

- 8 to 8.5 inches: R-25

- 9.5 inches: R-30

- 12 inches: R-38 rating

Cost Comparison: Foam Board vs. Fiberglass Insulation

When comparing costs based on R-value per square foot, fiberglass insulation is priced at less than 50% of that of rigid foam board insulation.

For instance, insulating a wall section of 10 square feet to an R-value of 15 using fiberglass insulation typically ranges from $3.40 to $4.00. In contrast, achieving a similar R-value with rigid foam insulation is approximately $10.

Fiberglass insulation generates less waste compared to other materials. When rigid foam is trimmed to fit, it often results in small scraps and thin strips that are nearly impossible to use. In contrast, fiberglass insulation can be easily torn and fitted into tight spaces, resulting in minimal waste.

Simple Installation Process

Rigid foam and fiberglass each offer distinct advantages and disadvantages during installation. The primary benefit of rigid foam is that it is a clean product that does not cause irritation. On the other hand, fiberglass is advantageous due to its flexibility, allowing it to conform to various obstacles.

Rigid Foam Insulation

- Rigid foam can be trimmed using a fine-toothed saw or can be sliced and broken apart similar to drywall using a utility knife.

- Foam doesn’t necessitate complete protective gear against fibers like fiberglass does, but it’s still advisable to wear a dust mask.

- The inflexible nature of rigid foam prevents it from adjusting to obstacles within the wall, including wires, outlets, junction boxes, and bracing. Therefore, it is essential to meticulously cut the foam to fit around these impediments.

- Since achieving a secure seal with rigid foam can be challenging, it may be essential to use expandable foam or caulking to fill in narrow spaces between the foam and the framing components.

- Foil-faced polyisocyanurate foam board insulation acts as a vapor barrier on its own, eliminating the need for an extra vapor barrier. In contrast, rigid foam board insulation that lacks a foil layer might require an additional vapor barrier.

Fiberglass Thermal Insulation

- Fiberglass insulation is adaptable and can easily conform to vents, electrical wires, and wall supports.

- Fiberglass insulation can be trimmed using sharp scissors or a utility knife.

- Fiberglass insulation can cause irritation to the skin, eyes, and respiratory system. To ensure your safety during installation, it is advisable to use a respirator instead of a dust mask, and to wear protective eyewear, gloves, and long-sleeved clothing along with long pants.

- Fiberglass needs to be secured to the studs using staples.

- Fiberglass insulation features a vapor-retarding layer that can potentially remove the requirement for an additional vapor barrier.

Durability

Both rigid foam and fiberglass have a lifespan of 80 to 100 years, but fiberglass insulation is more susceptible to water damage.

Rigid Foam Insulation

Rigid foam insulation offers greater durability against water damage and pest infestations compared to fiberglass insulation, typically resulting in a longer lifespan. Nonetheless, despite its superior resistance, rigid foam is not entirely waterproof. For residences located in humid environments, it is advisable to opt for higher-density rigid foam.

Fiberglass Thermal Insulation

Fiberglass insulation lacks water resistance and can easily become wet, leading to issues such as mold growth and decay. Additionally, it can attract insects and rodents, which may create nests and leave behind droppings. If fiberglass insulation suffers from water damage or pest infestation, it needs to be replaced.

Effects on Air Quality

Many open-cell insulation materials, such as fiberglass, have the ability to retain moisture, which may affect the quality of indoor air if mold and mildew develop.

Rigid Foam Insulation

Certain types of rigid foam may release volatile organic compounds (VOCs), with the highest levels of off-gassing occurring right after installation. Additionally, some foams may contain additives that can harm the ozone layer, thereby exacerbating global warming and air pollution.

Fiberglass Thermal Insulation

Fiberglass contains minuscule fibers that can become airborne during installation and as time passes. These fibers can impact the quality of the air. Additionally, if pests start to inhabit the materials, their waste, including urine and feces, can further degrade air quality.

Fiberglass materials of inferior quality often include additives such as formaldehyde, which are classified as volatile organic compounds (VOCs) and can pose risks to human health. In contrast, premium fiberglass products, such as those certified by Greenguard, are designed to enhance air quality and comply with stricter emission regulations.

Selecting Between Rigid Foam and Fiberglass Insulation

The dimensions of your project, along with the climate and financial constraints, will ultimately influence your insulation selections. Rigid foam insulation boasts the highest R-value, offers enhanced durability, and resists moisture. As a result, it is frequently the preferred option for insulating basements.

Fiberglass is a more affordable and simpler option for installation. While it doesn’t provide as much insulation as rigid foam, it remains effective and is commonly utilized as insulation within walls, in the wall framework, as well as in ceilings, joists, and roof rafters in residential buildings.