Nails are available in various sizes, materials, and shaft designs to enhance their grip in various woodworking projects. Use this guide to determine the appropriate nail size and type for your specific needs.

Contents

- 1 Varieties of Nails

- 2 Standard Nail

- 3 Box Nail

- 4 Double-Ended Nail

- 5 Annular Ring Nail or Ring Shank Nail

- 6 Masonry or Concrete Fastener

- 7 Finish Nail or Trim Nail

- 8 Brad Nail

- 9 Roofing Nail or Clout Nail

- 10 Penny Nail Designations

- 11 Nail Tips

- 12 Nail Shafts

- 13 Nail Tops

- 14 Nail Finishes

- 15 Different Metal Types Used for Nails

Varieties of Nails

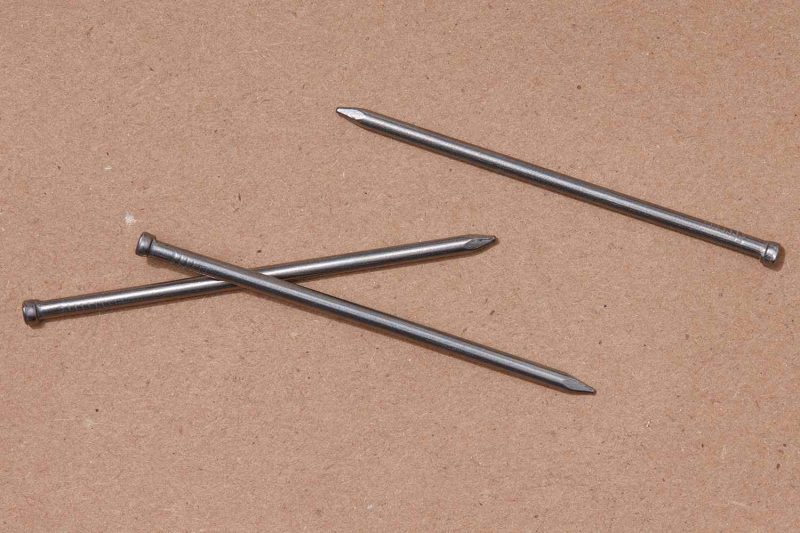

Standard Nail

Common nails are utilized in various construction tasks, particularly in framing and structural applications. These nails feature a robust shank, a broad head, and a pointed tip shaped like a diamond. They are primarily used with dimensional lumber, like two-by-fours. While their thickness provides strength, it also increases the risk of splitting the wood compared to thinner nails. A specific variant of the common nail is the sinker, which has a slightly slimmer shank and a uniquely designed head that allows it to be driven flush with the wood’s surface.

Box Nail

Box nails resemble common nails and sinkers but feature a more slender shank. They are ideal for use with thinner wood products, like 1x (3/4-inch-thick) lumber and exterior trim. However, box nails are not recommended for structural applications due to their reduced strength and holding capacity compared to common nails. The thinner shank design minimizes the risk of splitting thinner materials.

Double-Ended Nail

Duplex head nails feature two distinct heads: one positioned at the top and another positioned slightly below it. These nails are primarily utilized in temporary construction applications, including formwork for concrete pouring and the attachment of temporary cleats in roofing projects. The nail is driven in until the lower head is level with the surface of the wood. When the project needs to be taken apart, the nail can be removed by leveraging the upper head with a hammer’s claw or a pull bar.

Annular Ring Nail or Ring Shank Nail

A ring shank nail, also known as an annular ring nail, features a series of rings along its shank, providing enhanced grip and increased resistance to being pulled from the wood. These nails are frequently utilized in the installation of subflooring, as their superior holding strength can help minimize floor squeaks. Other types of nails that may also have rings include drywall nails and deck board nails, which are designed to offer better holding capabilities.

Proceed to 5 out of 8 listed below.

Masonry or Concrete Fastener

Masonry and concrete nails are robust, short, and sturdy fasteners specifically crafted for use in concrete, concrete blocks, and mortar joints, making them essential for masonry projects. Constructed from hardened steel, these nails typically feature grooves along their shafts, which facilitate their penetration into tough materials by allowing them to spiral as they are hammered in.

Finish Nail or Trim Nail

A finish or casing nail features a small, slightly rounded head that is marginally larger than the nail shaft. This head is specifically designed to accommodate the pointed end of a nail set, facilitating the countersinking of the nail without the risk of slipping. Essentially, a casing nail is a larger version of a finishing nail. It is frequently utilized for the installation of exterior trim boards as well as for securing door frames and trim. Casing nails are typically galvanized to prevent corrosion. The head of the nail is tapered and can be set either flush with or just beneath the surface of the wood.

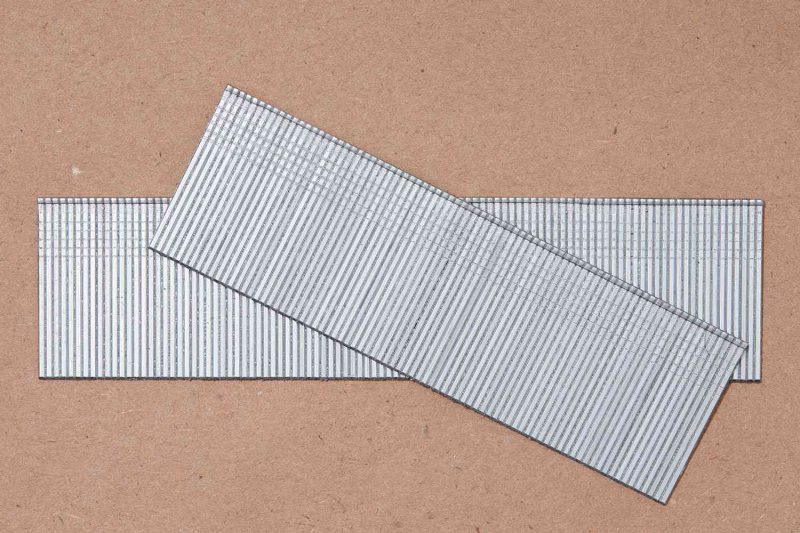

Brad Nail

Brad nails, often referred to as brads, feature slender shanks akin to those of finishing nails. They are primarily utilized in lightweight woodworking projects. Due to their narrow shank and minimal head size, brad nails minimize the risk of wood splitting. Since they are challenging to drive in manually, they are generally employed with a nail gun.

Roofing Nail or Clout Nail

Roofing nails, often referred to as clout nails, feature a short shaft and a broad, flat, and thin head. These nails are designed to secure shingles, roofing felt, or sheet metal to wooden surfaces. Their shanks may be either smooth or ringed to enhance resistance to pull-out.

Penny Nail Designations

The penny nail classification employs designations such as 10d, 16d, etc. This system indicates the length of the nails, with each successive number signifying an increase of 1/4 inch in length.

| Penny Name | Length (Imperial) | Length (Metric) |

| 2d | 1-inch | 25.4 mm |

| 3d | 1-1/4-inch | 31.7 mm |

| 4d | 1-1/2-inch | 38.1 mm |

| 5d | 1-3/4-inch | 44.4 mm |

| 6d | 2-inch | 50.8 mm |

| 7d | 2-1/4-inch | 57.1 mm |

| 8d | 2-1/2-inch | 63.5 mm |

| 9d | 2-3/4-inch | 69.8 mm |

| 10d | 3-inch | 76.2 mm |

| 12d | 3-1/4-inch | 82.5 mm |

| 16d | 3-1/2-inch | 88.9 mm |

| 20d | 4-inch | 101.6 mm |

Nail Tips

The tip of a nail refers to the end that is struck or inserted into the material.

- Diamond tip: The diamond-shaped tip is the most prevalent design for nails. This shape facilitates easy driving of the nail and reduces the risk of wood splitting.

- A blunt tip on a nail can make it harder to drive into the material, but it is specifically intended to minimize the risk of wood splitting. Some woodworkers intentionally blunt the tip of the nail to further reduce the chances of splitting the wood.

Nail Shafts

The shank of the nail refers to its elongated section. This portion is the most robust and provides the greatest gripping strength.

- A smooth shank allows for effortless insertion but can be removed with equal ease.

- A spiral shank, designed for hardwood applications, twists as it penetrates the material, making it less likely to be pulled out.

- A ring-shank nail grips the wood fibers as it is hammered in, particularly in softwoods, providing a strong hold that prevents it from being pulled out.

Nail Tops

The nail head refers to the flat, typically circular part located at the end opposite the pointed tip. Standard flat heads provide an extensive surface area for striking.

- Checkered nail heads: The flat heads featuring a grid design help to keep the hammer securely in place during strikes, reducing the risk of slipping.

- Countersunk and cupped nail heads feature a conical design, allowing them to be easily embedded just beneath the surface for a more polished appearance.

Nail Finishes

Specialized coatings enhance the lubrication of the nail shank, boosting its strength and driving performance. A nail without any coating is commonly referred to as a bright nail.

- Zinc-coated galvanized nails provide a safeguard against corrosion.

- Vinyl coatings enhance both grip and retention strength.

- Black phosphate coatings are applied to indoor nails to enhance their adhesion to various interior materials.

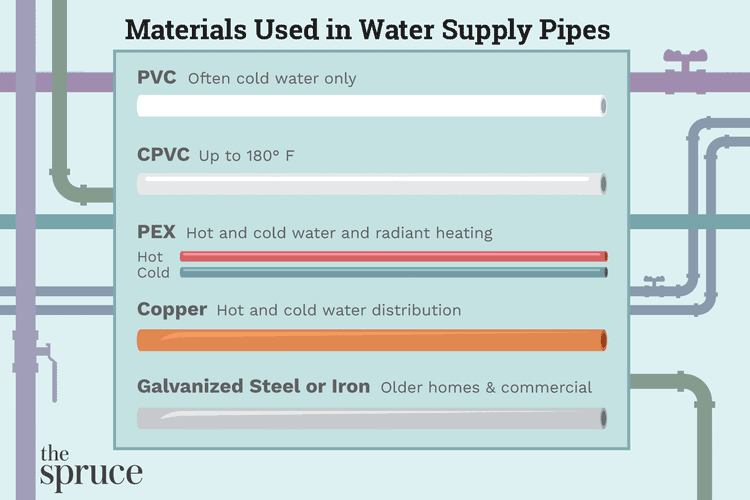

Different Metal Types Used for Nails

Nails can be crafted from various materials, including standard steel, stainless steel, brass, copper, or aluminum. The majority of nails used in construction are made of steel, and they are frequently coated.

Outdoor nails are typically coated with zinc through galvanization or hot-dipping to enhance their resistance to the elements. When working with pressure-treated wood, using hot-dipped nails is crucial to avoid corrosion from the chemicals present in the lumber.

Stainless steel is utilized for outdoor purposes as well, although the cost of stainless steel nails is significantly higher compared to zinc-coated nails.

What types of nails offer the greatest durability?

Stainless steel nails offer exceptional durability, making them ideal for outdoor projects such as fences, decks, and sheds. However, they tend to be pricier compared to galvanized or zinc-coated nails.

What distinguishes framing nails from common nails?

Framing nails feature a more slender shank and possess heads that are thin and nearly flat. In contrast, common nails are characterized by a thicker shank and more robust heads.